1. Shock/Pressure Absorbing of ArFLEX

During aerobic exercise/sport activities , the pressure given to feet is around 5 times of body weight . HWA CHING FOAM has recently developed the ArFLEX material , compare to regular PU foam ; it has very high resilience property which could absorb most of the pressure from body to feet . This minimizes the chance of feet injury during sports activities .

2. Comfortable Feet With ArFLEX

While regular walking or sports exercise , if shoe insoles are too hard or lack of resilience , it gives people impression that this pair of shoes is uncomfortable . Thus , a more comfortable material-ArFLEX , is recommended for shoe insole to match a pair of good shoes . ArFLEX foam has a much higher elongation value comparing to EVA ; when the foot bends during walking , it provides more comfort feeling .

3. Slim and Light Weight of ArFLEX

Due to the high resilience property of ArFLEX , only a very thin layer of it is required to provide same or better performance in supporting body weight . Unlike EVA shoe insole is normally 6mm to over 10mm , ArFLEX shoe insole could be as thin as 3mm and still comfortable . ArFLEX is a modern material/choice for shoe insole allowing designers more space and imagination in a pair of good shoes .

4. Anti-Bacteria of ArFLEX

In the ArFLEX formulation , we can choose to use anti-bacteria additives . This will prevent germs from growing in a pair of shoes, in some cases help to reduce odors .

6. Pressure resistance of ArFLEX

Compare to EVA , ArFLEX foam has a much lower value of ‟Compression Set” . This means that the shape of EVA shoe insole will change shape much easier and faster than ArFLEX shoe insole when pressure is given . ArFLEX shoe insole will extend the life time of a pair of good shoes .

|

Product # |

Density Kg/m3 |

Hardness Asker-C |

Tensile Strength Kg/cm2 |

Elongation % |

Tear Strength Kg/cm |

Compression % |

|

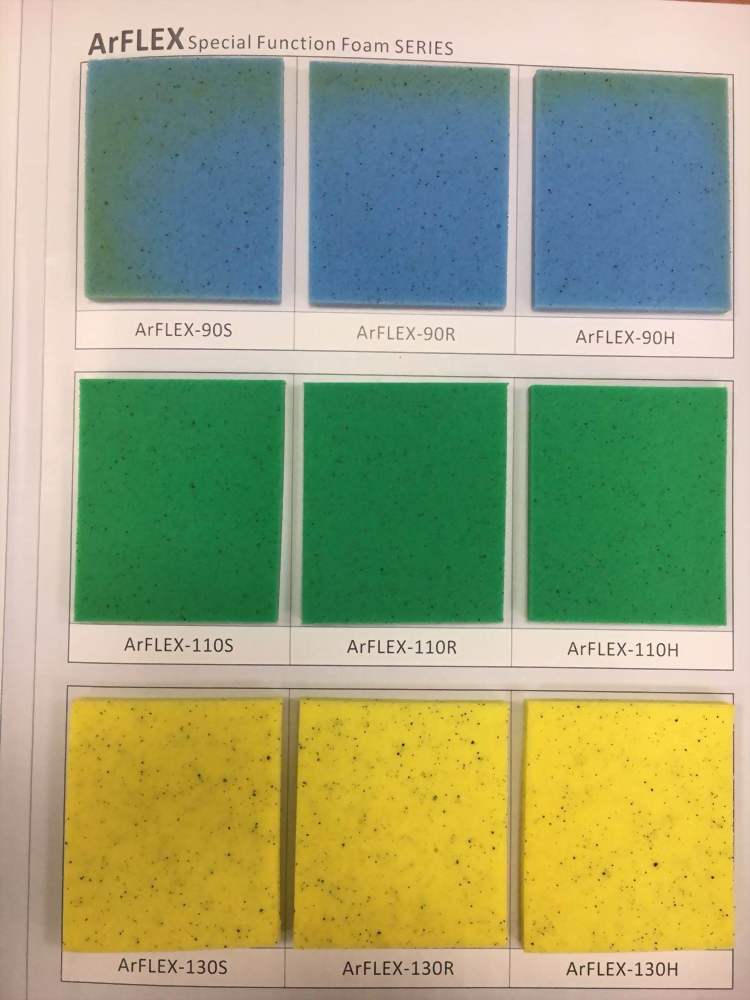

ArFLEX-90S |

90±10 |

5~15 |

2.5↑ |

80↑ |

1.50↑ |

25↓ |

|

ArFLEX-90R |

90±10 |

15~25 |

2.5↑ |

80↑ |

1.50↑ |

25↓ |

|

ArFLEX-90H |

90±10 |

25~35 |

3.0↑ |

80↑ |

2.00↑ |

25↓ |

|

ArFLEX-110S |

110±10 |

5~15 |

3.0↑ |

100↑ |

1.50↑ |

20↓ |

|

ArFLEX-110R |

110±10 |

15~25 |

3.0↑ |

100↑ |

2.00↑ |

20↓ |

|

ArFLEX-110H |

110±10 |

25~35 |

3.5↑ |

100↑ |

2.00↑ |

20↓ |

|

ArFLEX-130S |

130±10 |

5~15 |

3.0↑ |

100↑ |

1.50↑ |

15↓ |

|

ArFLEX-130R |

130±10 |

15~25 |

3.5↑ |

100↑ |

2.00↑ |

15↓ |

|

ArFLEX-130H |

130±10 |

25~35 |

4.0↑ |

100↑ |

2.50↑ |

15↓ |